What is an accident and why should it be investigated?

UMUKPEDI EMMANUEL

The term "accident" can be defined as an unplanned event that interrupts the completion of an activity, and that may (or may not) include injury or property damage.

An incident usually refers to an unexpected event that did not cause injury or damage this time but had the potential. "Near miss" or "dangerous occurrence" are also terms for an event that could have caused harm but did not.

Please note: The term incident is used in some situations and jurisdictions to cover both an "accident" and "incident". It is argued that the word "accident" implies that the event was related to fate or chance. When the root cause is determined, it is usually found that many events were predictable and could have been prevented if the right actions were taken -- making the event not one of fate or chance (thus, the word incident is used). For simplicity, we will use the term accident to mean all of the above events.

The information that follows is intended to be a general guide for supervisors or joint occupational health and safety committee members. When accidents are investigated, the emphasis should be concentrated on finding the root cause of the accident rather than the investigation procedure itself so you can prevent it from happening again. The purpose is to find facts that can lead to actions, not to find fault. Always look for deeper causes. Do not simply record the steps of the event.

Reasons to investigate a workplace accident include:

- most importantly, to find out the cause of accidents and to prevent similar accidents in the future

- to fulfill any legal requirements

- to determine the cost of an accident

- to determine compliance with applicable safety regulations

- to process workers' compensation claims

Incidents that involve no injury or property damage should still be investigated to determine the hazards that should be corrected. The same principles apply to a quick inquiry of a minor incident and to the more formal investigation of a serious event.

Who should do the accident investigating?

Ideally, an investigation would be conducted by someone experienced in accident causation, experienced in investigative techniques, fully knowledgeable of the work processes, procedures, persons, and industrial relations environment of a particular situation.

Some jurisdictions provide guidance such as requiring that it must be conducted jointly, with both management and labour represented, or that the investigators must be knowledgeable about the work processes involved.

In most cases, the supervisor should help investigate the event. Other members of the team can include:

- employees with knowledge of the work

- safety officer

- health and safety committee

- union representative, if applicable

- employees with experience in investigations

- "outside" expert

- representative from local government

Should the immediate supervisor be on the team?

The advantage is that this person is likely to know most about the work and persons involved and the current conditions. Furthermore, the supervisor can usually take immediate remedial action. The counter argument is that there may be an attempt to gloss over the supervisors shortcomings in the accident. This situation should not arise if the accident is investigated by a team of people, and if the worker representative(s) and the members review all accident investigation reports thoroughly.

Why look for the root cause?

An investigator who believes that accidents are caused by unsafe conditions will likely try to uncover conditions as causes. On the other hand, one who believes they are caused by unsafe acts will attempt to find the human errors that are causes. Therefore, it is necessary to examine some underlying factors in a chain of events that ends in an accident.

The important point is that even in the most seemingly straightforward accidents,seldom, if ever, is there only a single cause. For example, an "investigation" which concludes that an accident was due to worker carelessness, and goes no further, fails to seek answers to several important questions such as:

- Was the worker distracted? If yes, why was the worker distracted?

- Was a safe work procedure being followed? If not, why not?

- Were safety devices in order? If not, why not?

- Was the worker trained? If not, why not?

An inquiry that answers these and related questions will probably reveal conditions that are more open to correction than attempts to prevent "carelessness".

What are the steps involved in investigating an accident?

The accident investigation process involves the following steps:

- Report the accident occurrence to a designated person within the organization

- Provide first aid and medical care to injured person(s) and prevent further injuries or damage

- Investigate the accident

- Identify the causes

- Report the findings

- Develop a plan for corrective action

- Implement the plan

- Evaluate the effectiveness of the corrective action

- Make changes for continuous improvement

As little time as possible should be lost between the moment of an accident or near miss and the beginning of the investigation. In this way, one is most likely to be able to observe the conditions as they were at the time, prevent disturbance of evidence, and identify witnesses. The tools that members of the investigating team may need (pencil, paper, camera, film, camera flash, tape measure, etc.) should be immediately available so that no time is wasted.

What should be looked at as the cause of an accident?

Accident Causation Models

Many models of accident causation have been proposed, ranging from Heinrich's domino theory to the sophisticated Management Oversight and Risk Tree (MORT).

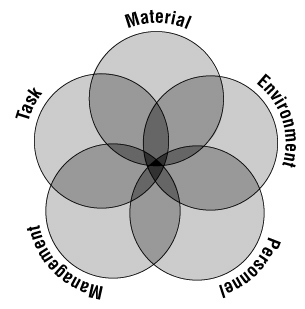

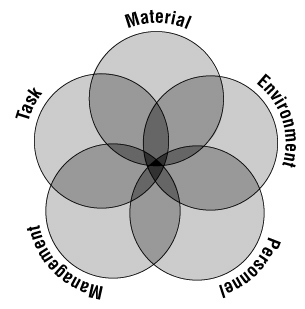

The simple model shown in Figure 1 attempts to illustrate that the causes of any accident can be grouped into five categories - task, material, environment, personnel, and management. When this model is used, possible causes in each category should be investigated. Each category is examined more closely below. Remember that these are sample questions only: no attempt has been made to develop a comprehensive checklist.

Figure 1: Accident Causation

Task

Here the actual work procedure being used at the time of the accident is explored. Members of the accident investigation team will look for answers to questions such as:

- Was a safe work procedure used?

- Had conditions changed to make the normal procedure unsafe?

- Were the appropriate tools and materials available?

- Were they used?

- Were safety devices working properly?

- Was lockout used when necessary?

For most of these questions, an important follow-up question is "If not, why not?"

Material

To seek out possible causes resulting from the equipment and materials used, investigators might ask:

- Was there an equipment failure?

- What caused it to fail?

- Was the machinery poorly designed?

- Were hazardous substances involved?

- Were they clearly identified?

- Was a less hazardous alternative substance possible and available?

- Was the raw material substandard in some way?

- Should personal protective equipment (PPE) have been used?

- Was the PPE used?

- Were users of PPE properly trained?

Again, each time the answer reveals an unsafe condition, the investigator must ask whythis situation was allowed to exist.

Environment

The physical environment, and especially sudden changes to that environment, are factors that need to be identified. The situation at the time of the accident is what is important, not what the "usual" conditions were. For example, accident investigators may want to know:

- What were the weather conditions?

- Was poor housekeeping a problem?

- Was it too hot or too cold?

- Was noise a problem?

- Was there adequate light?

- Were toxic or hazardous gases, dusts, or fumes present?

Personnel

The physical and mental condition of those individuals directly involved in the event must be explored. The purpose for investigating the accident is not to establish blame against someone but the inquiry will not be complete unless personal characteristics are considered. Some factors will remain essentially constant while others may vary from day to day:

- Were workers experienced in the work being done?

- Had they been adequately trained?

- Can they physically do the work?

- What was the status of their health?

- Were they tired?

- Were they under stress (work or personal)?

Management

Management holds the legal responsibility for the safety of the workplace and therefore the role of supervisors and higher management and the role or presence of management systems must always be considered in an accident investigation. Failures of management systems are often found to be direct or indirect factors in accidents. Ask questions such as:

- Were safety rules communicated to and understood by all employees?

- Were written procedures and orientation available?

- Were they being enforced?

- Was there adequate supervision?

- Were workers trained to do the work?

- Had hazards been previously identified?

- Had procedures been developed to overcome them?

- Were unsafe conditions corrected?

- Was regular maintenance of equipment carried out?

- Were regular safety inspections carried out?

This model of accident investigations provides a guide for uncovering all possible causes and reduces the likelihood of looking at facts in isolation. Some investigators may prefer to place some of the sample questions in different categories; however, the categories are not important, as long as each pertinent question is asked. Obviously there is considerable overlap between categories; this reflects the situation in real life. Again it should be emphasized that the above sample questions do not make up a complete checklist, but are examples only.

How are the facts collected?

The steps in accident investigation are simple: the accident investigators gather information, analyze it, draw conclusions, and make recommendations. Although the procedures are straightforward, each step can have its pitfalls. As mentioned above, an open mind is necessary in accident investigation: preconceived notions may result in some wrong paths being followed while leaving some significant facts uncovered. All possible causes should be considered. Making notes of ideas as they occur is a good practice but conclusions should not be drawn until all the information is gathered.

Injured workers(s)

The most important immediate tasks--rescue operations, medical treatment of the injured, and prevention of further injuries--have priority and others must not interfere with these activities. When these matters are under control, the investigators can start their work.

Physical Evidence

Before attempting to gather information, examine the site for a quick overview, take steps to preserve evidence, and identify all witnesses. In some jurisdictions, an accident site must not be disturbed without prior approval from appropriate government officials such as the coroner, inspector, or police. Physical evidence is probably the most non-controversial information available. It is also subject to rapid change or obliteration; therefore, it should be the first to be recorded. Based on your knowledge of the work process, you may want to check items such as:

- positions of injured workers

- equipment being used

- materials or chemicals being used

- safety devices in use

- position of appropriate guards

- position of controls of machinery

- damage to equipment

- housekeeping of area

- weather conditions

- lighting levels

- noise levels

- time of day

You may want to take photographs before anything is moved, both of the general area and specific items. Later careful study of these may reveal conditions or observations missed previously. Sketches of the accident scene based on measurements taken may also help in subsequent analysis and will clarify any written reports. Broken equipment, debris, and samples of materials involved may be removed for further analysis by appropriate experts. Even if photographs are taken, written notes about the location of these items at the accident scene should be prepared.

Eyewitness Accounts

Although there may be occasions when you are unable to do so, every effort should be made to interview witnesses. In some situations witnesses may be your primary source of information because you may be called upon to investigate an accident without being able to examine the scene immediately after the event. Because witnesses may be under severe emotional stress or afraid to be completely open for fear of recrimination, interviewing witnesses is probably the hardest task facing an investigator.

Witnesses should be kept apart and interviewed as soon as possible after the accident. If witnesses have an opportunity to discuss the event among themselves, individual perceptions may be lost in the normal process of accepting a consensus view where doubt exists about the facts.

Witnesses should be interviewed alone, rather than in a group. You may decide to interview a witness at the scene of the accident where it is easier to establish the positions of each person involved and to obtain a description of the events. On the other hand, it may be preferable to carry out interviews in a quiet office where there will be fewer distractions. The decision may depend in part on the nature of the accident and the mental state of the witnesses.

Interviewing

Interviewing is an art that cannot be given justice in a brief document such as this, but a few do's and don'ts can be mentioned. The purpose of the interview is to establish an understanding with the witness and to obtain his or her own words describing the event:

DO...

- put the witness, who is probably upset, at ease

- emphasize the real reason for the investigation, to determine what happened and why

- let the witness talk, listen

- confirm that you have the statement correct

- try to sense any underlying feelings of the witness

- make short notes or ask someone else on the team to take them during the interview

- ask if it is okay to record the interview, if you are doing so

- close on a positive note

DO NOT...

- intimidate the witness

- interrupt

- prompt

- ask leading questions

- show your own emotions

- jump to conclusions

Ask open-ended questions that cannot be answered by simply "yes" or "no". The actual questions you ask the witness will naturally vary with each accident, but there are some general questions that should be asked each time:

- Where were you at the time of the accident?

- What were you doing at the time?

- What did you see, hear?

- What were the environmental conditions (weather, light, noise, etc.) at the time?

- What was (were) the injured worker(s) doing at the time?

- In your opinion, what caused the accident?

- How might similar accidents be prevented in the future?

If you were not at the scene at the time, asking questions is a straightforward approach to establishing what happened. Obviously, care must be taken to assess the credibility of any statements made in the interviews. Answers to a first few questions will generally show how well the witness could actually observe what happened.

Another technique sometimes used to determine the sequence of events is to re-enact or replay them as they happened. Obviously, great care must be taken so that further injury or damage does not occur. A witness (usually the injured worker) is asked to reenact in slow motion the actions that preceded the accident.

Background Information

A third, and often an overlooked source of information, can be found in documents such as technical data sheets, health and safety committee minutes, inspection reports, company policies, maintenance reports, past accident reports, formalized safe-work procedures, and training reports. Any pertinent information should be studied to see what might have happened, and what changes might be recommended to prevent recurrence of similar accidents.

What should I know when making the analysis and conclusions?

At this stage of the investigation most of the facts about what happened and how it happened should be known. This has taken considerable effort to accomplish but it represents only the first half of the objective. Now comes the key question--why did it happen? To prevent recurrences of similar accidents, the investigators must find all possible answers to this question.

You have kept an open mind to all possibilities and looked for all pertinent facts. There may still be gaps in your understanding of the sequence of events that resulted in the accident. You may need to reinterview some witnesses to fill these gaps in your knowledge.

- When your analysis is complete, write down a step-by-step account of what happened (your conclusions) working back from the moment of the accident, listing all possible causes at each step. This is not extra work: it is a draft for part of the final report. Each conclusion should be checked to see if:

- it is supported by evidence

- the evidence is direct (physical or documentary) or based on eyewitness accounts, or

- the evidence is based on assumption.

This list serves as a final check on discrepancies that should be explained or eliminated.

Why should recommendations be made?

The most important final step is to come up with a set of well-considered recommendations designed to prevent recurrences of similar accidents. Once you are knowledgeable about the work processes involved and the overall situation in your organization, it should not be too difficult to come up with realistic recommendations. Recommendations should:

- be specific

- be constructive

- get at root causes

- identify contributing factors

Resist the temptation to make only general recommendations to save time and effort.

For example, you have determined that a blind corner contributed to an accident. Rather than just recommending "eliminate blind corners" it would be better to suggest:

- install mirrors at the northwest corner of building X (specific to this accident)

- install mirrors at blind corners where required throughout the worksite (general)

Never make recommendations about disciplining a person or persons who may have been at fault. This would not only be counter to the real purpose of the investigation, but it would jeopardize the chances for a free flow of information in future accident investigations.

In the unlikely event that you have not been able to determine the causes of an accident with any certainty, you probably still have uncovered safety weaknesses in the operation. It is appropriate that recommendations be made to correct these deficiencies.

The Written Report

If your organization has a standard form that must be used, you will have little choice in the form that your written report is to be presented. Nevertheless, you should be aware of, and try to overcome, shortcomings such as:

- If a limited space is provided for an answer, the tendency will be to answer in that space despite recommendations to "use back of form if necessary."

- If a checklist of causes is included, possible causes not listed may be overlooked.

- Headings such as "unsafe condition" will usually elicit a single response even when more than one unsafe condition exists.

- Differentiating between "primary cause" and "contributing factors" can be misleading. All accident causes are important and warrant consideration for possible corrective action.

Your previously prepared draft of the sequence of events can now be used to describe what happened. Remember that readers of your report do not have the intimate knowledge of the accident that you have so include all pertinent detail. Photographs and diagrams may save many words of description. Identify clearly where evidence is based on certain facts, eyewitness accounts, or your assumptions.

If doubt exists about any particular part, say so. The reasons for your conclusions should be stated and followed by your recommendations. Weed out extra material that is not required for a full understanding of the accident and its causes such as photographs that are not relevant and parts of the investigation that led you nowhere. The measure of a good accident report is quality, not quantity.

Always communicate your findings with workers, supervisors and management. Present your information 'in context' so everyone understands how the accident occurred and the actions in place to prevent it from happening again.

What should be done if the investigation reveals human error

A difficulty that has bothered many investigators is the idea that one does not want to lay blame. However, when a thorough worksite accident investigation reveals that some person or persons among management, supervisor, and the workers were apparently at fault, then this fact should be pointed out. The intention here is to remedy the situation, not to discipline an individual.

Failing to point out human failings that contributed to an accident will not only downgrade the quality of the investigation. Furthermore, it will also allow future accidents to happen from similar causes because they have not been addressed.

However never make recommendations about disciplining anyone who may be at fault. Any disciplinary steps should be done within the normal personnel procedures.

How should follow-up be handled?

Management is responsible for acting on the recommendations in the accident investigation report. The health and safety committee, if you have one, can monitor the progress of these actions.

Follow-up actions include:

- Respond to the recommendations in the report by explaining what can and cannot be done (and why or why not).

- Develop a timetable for corrective actions.

- Monitor that the scheduled actions have been completed.

- Check the condition of injured worker(s).

- Inform and train other workers at risk.

- Re-orient worker(s) on their return to work.